Who

could have believed that an accidental event of 1836 would prove to be a boon

for the coming age?

That 1836 event was the identification of a new element

"the new carbonate of hydrogen" when potassium metal was heated to

high temperatures by Edmund Davy producing a residue now known as potassium

carbide,

Today

we’ll discuss the potassium carbide which plays a major role in the formation of

acetylene gas today.

Potassium carbide

Potassium

carbide reacts with water and forms a new gas (acetylene). Which is flammable

and is mainly used in the gas welding process due to the extreme temperature given

by burning in combination with oxygen/air.

In the modern era, large quantities of acetylene gas are being consumed.

Although it is more economical to produce the gas at the site for use with the help of acetylene gas generators, it needs to be produced on a large scale in

other plants.

Acetylene gas generation

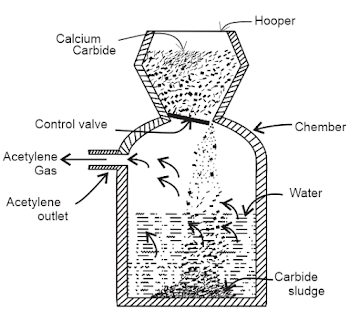

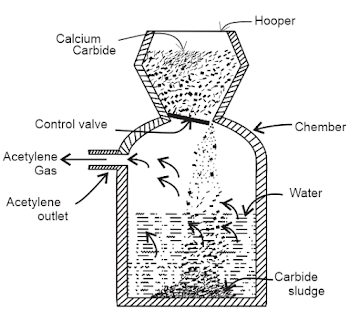

Acetylene gas is produced by "carbide-to-water" methods such as a generator unit feeding controlled amounts of calcium carbide into the water.

When these ingredients are mixed, acetylene gas is produced.

Acetylene gas generator

Generally, two types of acetylene gas generators are being used such as:

The low-pressure generator can also be called a portable generator, its output capacity is low.

it can produce acetylene about

above 30ft3/hr(15 ltr/min.).

- Medium pressure Generator

A medium pressure gas generator is more commonly used because this type of generator is considered stationary, it can deliver gas up to 0,6 bar (from 1-15 psi) of pressure. The acetylene production rate by a medium pressure gas generator is approximately 6000ft3/hr(3000 Ltr/min.

Operational concept

In general, acetylene gas generators are automatic ie it automatically controls the amount of calcium carbide falling into the water. As shown in the figure, the control valve opens and closes automatically when acetylene increases or decreases in the chamber.

Safety manners

Various components are additionally incorporated in this to make the operation of the acetylene generator safe.

Disadvantages

Although the acetylene gas generation process is cheap and beneficial, it also has some disadvantages such as:

- Gas generation by the process of carbide-to-water methods requires additional safety precautions.

- If a low-pressure type generator is used, there is a tendency for the pressure to fluctuate with the resulting unstable flame.

0 Comments

Thanks for your valuable time