Preface

As we know, the intense heat of the arc obstructs the temperature of the metal and reaches the melting point at the bottom of the arc.Distribution of heat.

When the temperature difference is present, the heat starts to move out of the energized zone and heats around the metal. In the welding process, a welder has to use skills to control the heat. While welding, heat enters the puddle which is often controlled by:Welding speed and through weaving or whipping, as described in the same way. The expansion of heat and the rate at which it is excluded, from the weld zone, is dependent on the following factors:

1 - conductance, of work material

2. The mass of the base metal throughout the weld area

3. Available paths for heat conduction

4. the weaving, technique

When compared to other materials, all metals are good conductors of heat. although, all metals are not equal in the

Ability to conduct heat. Such as aluminum is a good conductor

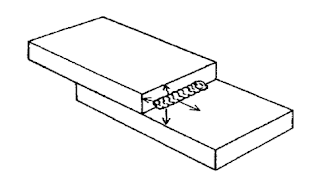

In the heat, metal than stainless steel, the weld area will cool faster than aluminum. In addition, heat will spread throughout the Aluminum plate more quickly. The heat will be extracted faster from lap

Joint than edge joint because the lap joint provides two paths or directions

The flow of heat compared to one direction for the edge joint. Are the way

With which heat can flow to certain weld joints

Factors affecting the distribution of heat in the weld zone:

welding technology

When welding, there are electrodes and arcs.

Sometimes intentionally moves in and out of the molten puddle

Metals, in a similar pattern, to lower the melt temperature

Preheat the metal ahead of the metal and weld.

This technology is called "Whipping:" when the molten metal puddle goes back

And in a similar way forward in the weld joint, in heat

The area close to the weld extends; This technique is called "weaving".

It is used to disperse heat and obtain a broad weld bead

Without retaining an extremely large puddle of molten metal.

0 Comments

Thanks for your valuable time